オカフーズの品質方針

「バラつきの無い商品」を、原料から使うところまでを

「安全」「安心」「ローコスト」に、お客様へ安定供給する。

オカフーズの安全・安心への取り組み

オカフーズはファブレス(自社で工場を持たない)メーカーですが、昭和50年の創業以来、安全・安心には熱心に取り組んでまいりました。昭和50年代のはじめから、三陸を中心とした委託先の水産加工工場に対して衛生管理を指導し、当時では珍しい白衣・マスク・帽子の着用と入室前点検を実施させていました。

当社は中山正夫技術士を顧問としてお迎えし、国内外の主要工場においては作業者全員に対して実務的な衛生管理の指導や勉強会を開催するなど、工場の衛生管理教育には力を入れております。また、海外生産が増えた今日では、「なぜ骨取りの魚が必要なのか、骨が残っているとどのような問題が発生するのか?」ということを工場作業者に理解して頂くための「日本研修」もおこなっております。

→パートナー工場紹介はこちら

原料買い付けから製品化までの管理体制

-

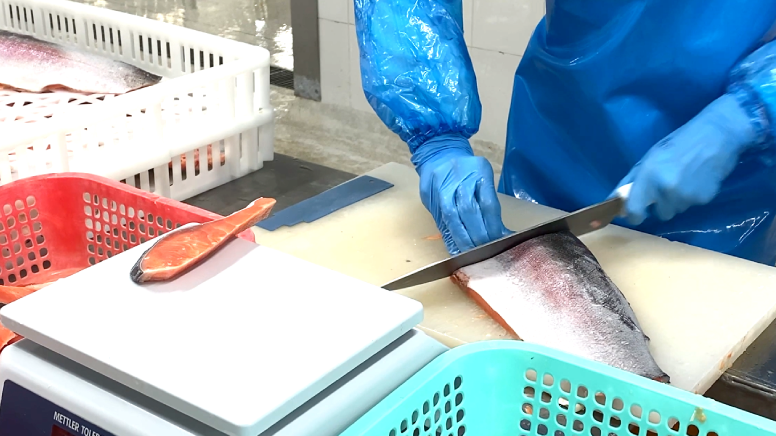

01.原料管理

原料調達のときには、オカフーズの経験豊富な買付担当者、もしくは依頼を受けた“魚のプロ”が直接現地で検品を行ったうえで買付を行っています。その際には原産地証明書が取れる原料のみを買付しておりますので、当社の製品はすべてトレーサビリティーが取れています。

-

02.工場管理

1.

当社が加工委託をしようとする工場については事前に当社のスタッフと外部専門家が必ず訪問し、当社の品質方針と合致した工場にのみ契約しています。

2.

また、当社は工場長などのマネージャーや現場管理者の育成を最優先に考えています。これらの層が言われたことをただこなすだけではなく、自発的に考え継続的な改善ができるようになることが必要と考えております。そのために、当社スタッフや外部専門家が定期的に現地とコミュニケーションをとり、管理技術と改善マインドのレベルアップに注力しております。現場の作業者に対しても定期的に勉強会を開催しています。勉強会のテーマは品質に対する意識向上や技術の向上だけではなく、オカフーズ製品がどのように調理され、食べられているのかを知るというものもあります。そのことによって自分たちが日常行っている作業の意味・意義を深く理解できるようになります。

3.

さらに当社は工場内の作業台の照度調整や食事の改善、従業員寮の改善・環境美化など、労働環境のみならず生活環境の整備にも積極的に取り組んでおります。

-

03.製品管理

1.

海外工場で製造される製品については、原料受け入れ時および製品化後に工場内の品質検査室で衛生検査をおこない、日本の法律が定める基準が満たされた安心・安全な製品のみを出荷しております。

2.

新商品等は、工場出荷前及び製品入荷時に初期流動管理のための検査をおこない、品質のバラつきが無いかを確認しております。

-

04.保管・物流管理

当社製品の保管から配送、納品までは、冷凍専門物流会社様に一括して委託し、保管温度や在庫の賞味期限管理、出荷履歴、配送中の温度管理・記録等を一元的に管理しております。

「使うところまでを安全・安心に」の

実現のために

当社製品を「安全・安心」にご使用いただくために、実際にご使用いただいている調理師・栄養士の皆さまや、お取扱いいただいている販売店の皆さまに向けた勉強会を開催しております。また、「お魚を楽しく食べるおもしろ辞典」や「お魚の生態Q&A」などのお役に立つ知識・事例が記載されたパンフレットを発行しお配りしております。そのほか展示会やセミナー、ホームページなどにおいても製品の仕様やご使用方法、また魚の特性などをご説明する機会を積極的に設けております。