- TOP>

- Company Information>

- Management Philosophy | Oka Foods

私たちは、ブランドオーナーとしての自覚を持ち

お客様の声に真摯に耳を傾け

期待以上の商品・サービスの提供を通じて

ステークホルダーの皆様の信頼にお応えできるよう努めます。

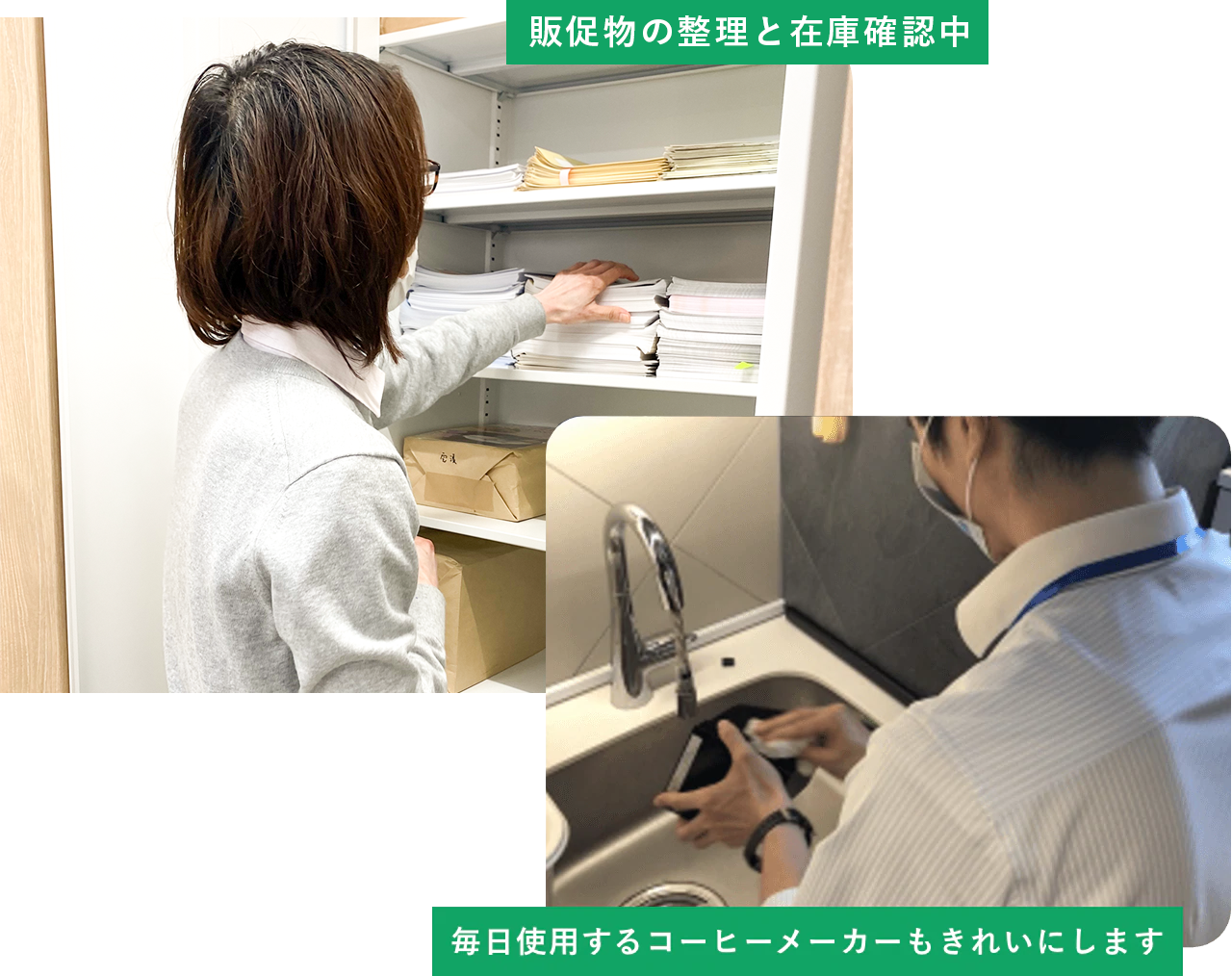

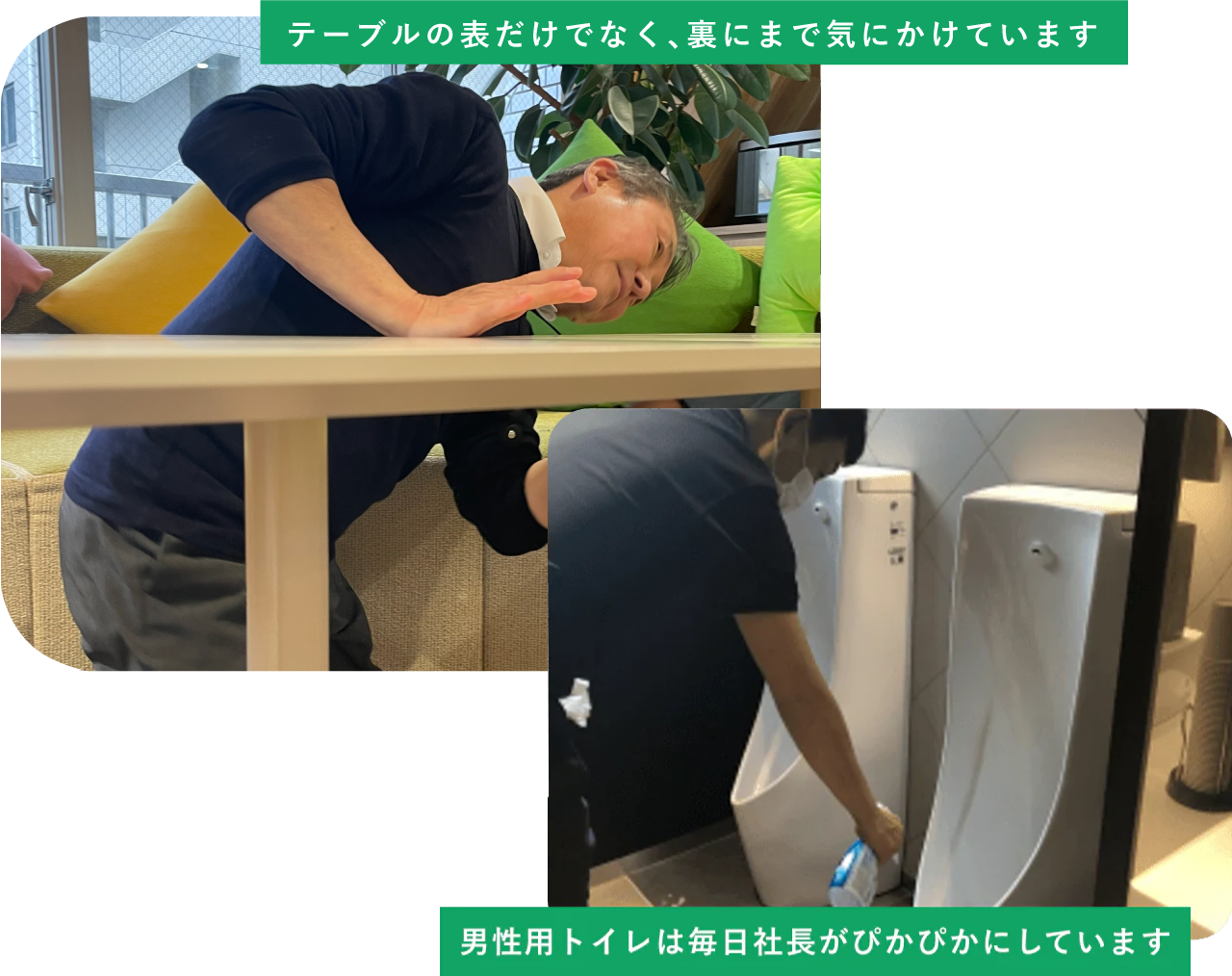

環境整備とはただの掃除ではなく、会社の文化として考えられています。 01. 環境整備を通じて、仕事のやり方・考え方に気付く習慣を身に付けること 02. 出社時でも在宅時でも仕事をやりやすくする環境を整えて、備えること この2つが環境整備の目的です。

基本

8:30から開始される全員で行うラジオ体操が終了した後、計画に沿って8時57分まで約25分間行います。環境整備はすべての活動において最優先としお客様からの電話応対を除き、「毎日」「必ず」「全員」で実行しています。また、お客様のところへ直接訪問をしたり出張などやむを得ず実行できなかった場合には、帰社後もしくは別の日に代替として環境整備を行います。

環境整備の時間を確保すべく予定を組み、今ある状態以上にするためにハード面、ソフト面の両輪で徹底的に考え実践をしています。

整理・整頓

要る物と要らない物を明確にし、要るもののみを残します。無駄な仕事を探し、その仕事はデジタイズを試み、やめるようにし、書類は電子化するようにしていますパソコンの中にある不要なデータ・メール・ファイルを削除をし、定期的にアプリの更新を行い、使う人のことを考え、データの保存は、決められたルールに従い保存・管理をしています。併せて「3定」(定位置・定品・定数)を徹底して推進しています。

後の人が使いやすいように、向きを揃え、少なくなったものは補充し、使ったものは必ず元の位置に正しい向き(一直線・水平・垂直)で戻します。

清潔

計画に沿って「今日はここだけ」という部分を決めて徹底的に汚れを落とします。

必要な清掃用品は揃え、必ず決まった場所に置きます。

社内をピカピカに磨きこみます。

特にトイレはピカピカに磨きこみます。

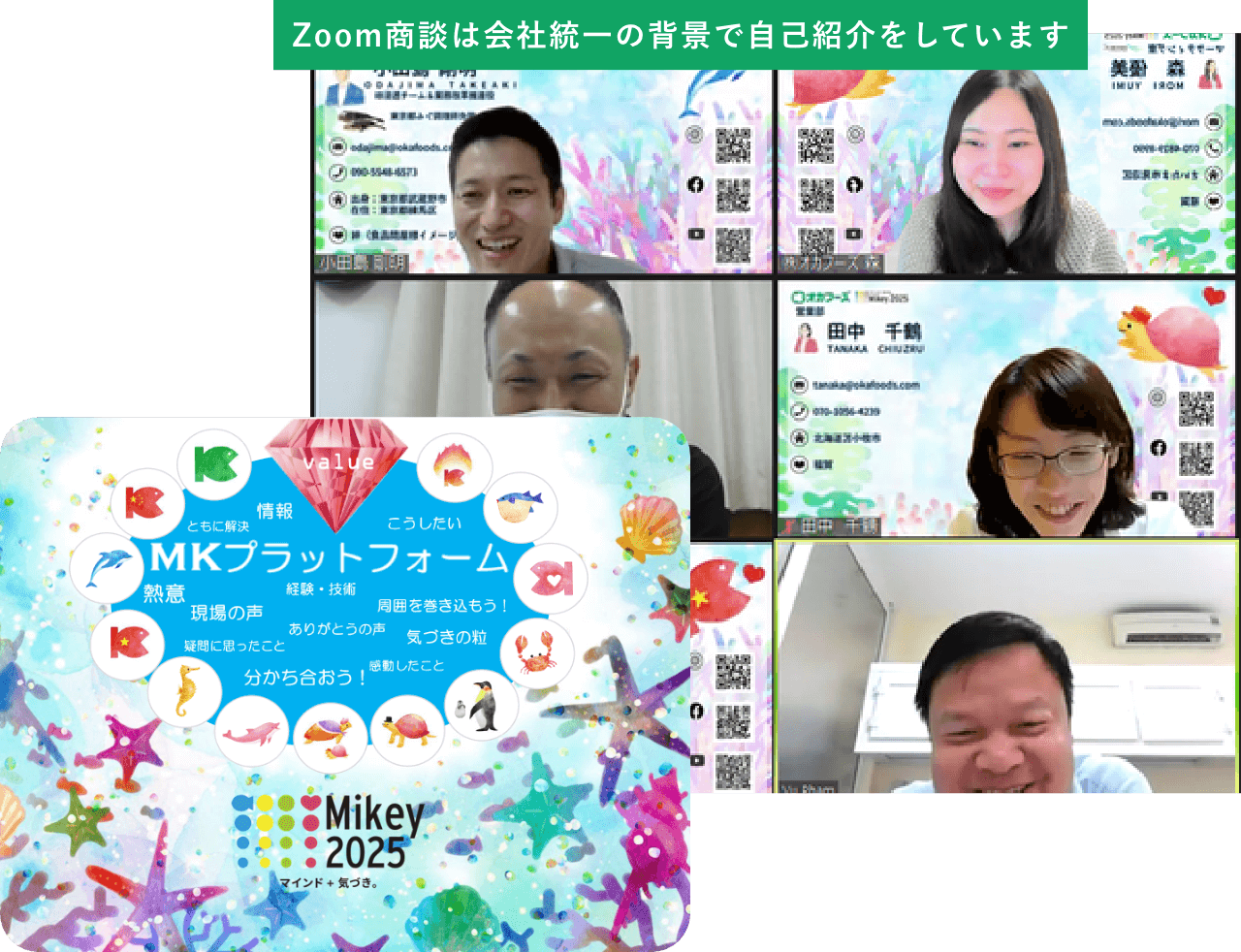

礼儀

名前を呼ばれた時には目線の高さを合わせて「はい」と返事をします。大きな声と笑顔で相手の名前を呼んで、相手より先にあいさつをし「一番爽やかなあいさつをする会社」を目指しています。

ZOOM(オンライン会議システム)を使用する際は、相手に顔を見えるようにし、ZOOM商談の場合でも、相手に失礼のないしっかりした服装をします。

MKプラットフォーム(業務日報)は必ず内容を確認し、「いいね!」やコメントも心掛けます。

環境整備のはじまり

代表取締役の岡が就任した1年後(2012年)から始まった円安は1ドル20円近くの下落となり、原価の大半を占める海外仕入原料価格が大幅に上昇したため、大幅な減収減益となってしまいました。何とか会社のスタイルを変えていかなければ生き残れないという危機感ばかり先行し、焦りが募っていました。

まずは、会社を改善するため、まずは社員の働きやすい環境を整えることにしました。年間の休日を増やしたり、コミュニケーションを活性化させる施策を考えたりし、その中でもメイン施策として始めたのが、「環境整備活動」です。

「掃除をしたところで、売上や利益が上がるわけないじゃないか!」と社員からはこのような懐疑的な目で見られることも多く、数か月もの間、毎朝たった岡が1人で事務所の掃除を続けていました。黙々と掃除をする姿を見た社員からは「とうとう社長がどうかしてしまったのでは」と心配する声があがったことすらありました。

このような孤立無援な中の2012年12月、朝礼後の25分間を使って環境整備活動を全社員が行うという方針を発表し、実行に移しました。

活動は始まったものの、最初はほとんどの社員が戸惑いを隠せず、掃除よりも売上を伸ばすことに時間を使ったらどうか、との声も依然として強くありました。しかしながら、毎日続けていくうちに少しずつ変化が出てくるようになりました。

「荷物置き用のカゴを用意したら、お客様が来たときにも便利になるのではないか」「会議室をもっとこうしたら使いやすくなるはず」というように、あるべき姿を追求することで、より良くしていこうとする思考の癖がついた社員が少しずつ出てきました。

そうした効果に多くの社員が徐々に気がつくにつれ、自主的に様々な環境改善を行うようになっていき、仕事にも意識的に生かしていくようになりました。

環境整備推進チーム

当社では環境整備を推進していくチームを結成しています。それぞれの部署から選ばれ、基本の任期は1年です。

定例のミーティングを行い、環境整備の基本の徹底や、よりよい会社にしていくためにはどのような仕組みや実践をしていけばいいかの話し合いをしています。社員が仕事をしやすい環境を整え、また無駄な仕事をなくすことで生まれた時間をステークホルダーの皆様への価値貢献活動に充てられるよう日々熱い想いをもって活動をしています。

-

Fighting

闘志がある

-

Improvement

改善・進歩

-

Shinka

進化

-

Henka

変化

上記の単語の頭文字からとったもので、社内で公募し採用されました。“魚専業”の当社に相応しい名称です。

オカフーズではそれ以前から環境整備活動を行なっておりました。

その活動をオフィスの整理整頓だけではなく、業務そのものも整理整頓する方向に拡げた形です。

FISH活動の目的は、当社が生産性の高い組織となって、ステークホルダーへのお役立ち活動など、

より付加価値の高い業務に社員が時間的リソースを振り向けられるようにすることです。

そのために抜本的かつ本質的な業務改善の仕組みの構築と、改善カルチャーを会社に定着させることを狙いました。

この業務改善活動は、会社全体を対象としバックオフィスだけではなく営業部門も対象としました。

さらに当初は役員も自分の業務フロー改善などの形で活動に参加しました。

活動のベースについて

FISH活動は、株式会社システム科学様のHIT法という方法に基づいて行われました。

HIT法では次のようなメリットがあったため採用しました。

01.コンサルタントが主導するのではなく、社員一人一人が主体的になって日々の自分の業務を見直し問題点を見つけて改善していくという点です。つまりこの活動を続けていくなかで、自然と改善力と改善マインドを身につけていきます。

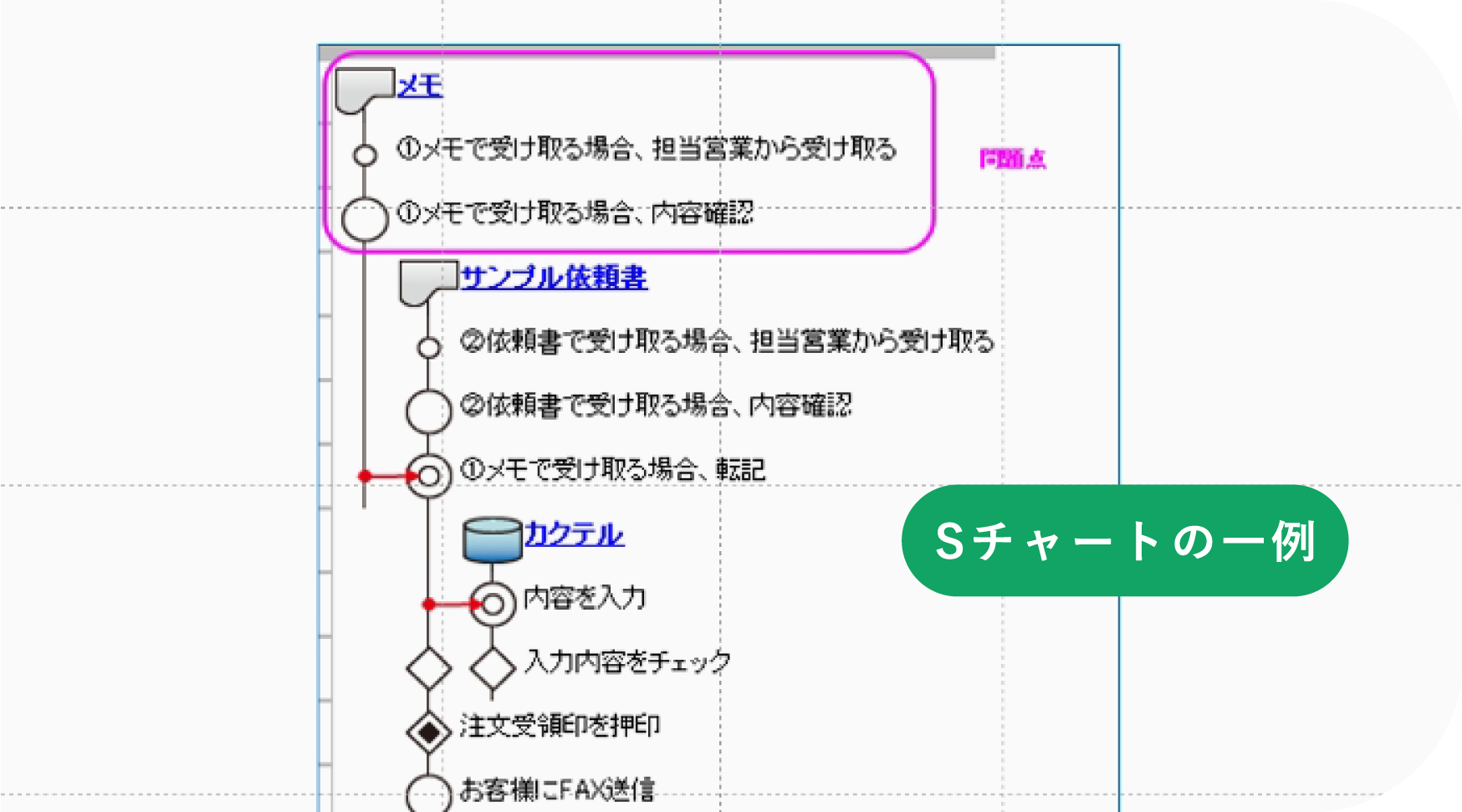

02.専用ソフトを使うことで、誰でも業務フローをSチャート化できるようになります。業務をSチャートの形で見える化することによって、作成者自身が自分の業務プロセスを形式知化できます。それだけではなく、自分のノウハウの継承や横展開が可能となり、さらに、業務プロセスを改善する際にもSチャートで明確に説明できるため、上長や関連部門の理解が得られやすいというメリットもあります。このツールはフローチャートを作成するだけではなく、誰がどれだけの業務時間を削減にしたか、部門ごとの今月の改善件数は何件か、途中でストップしている改善は何か、といったことも集計できるため、改善の進捗管理にも役に立ちます。

03.様々な業務改善コンサルティングの会社様をヒアリングしましたが、HIT法は改善効果が高く、その点も決め手の一つとなりました。FISH活動においてはトップダウンではなくボトムアップの推進体制を取りました。このような「社員がやりたがらない」活動は、一般的にはトップダウンの方が効率は良いとされています。しかし、当社では若手や中堅社員が中心となり、業務を改善する活動を通じて学習と成長をしていくことを狙い、マネージャーはフォロワーに徹するという形にいたしました。

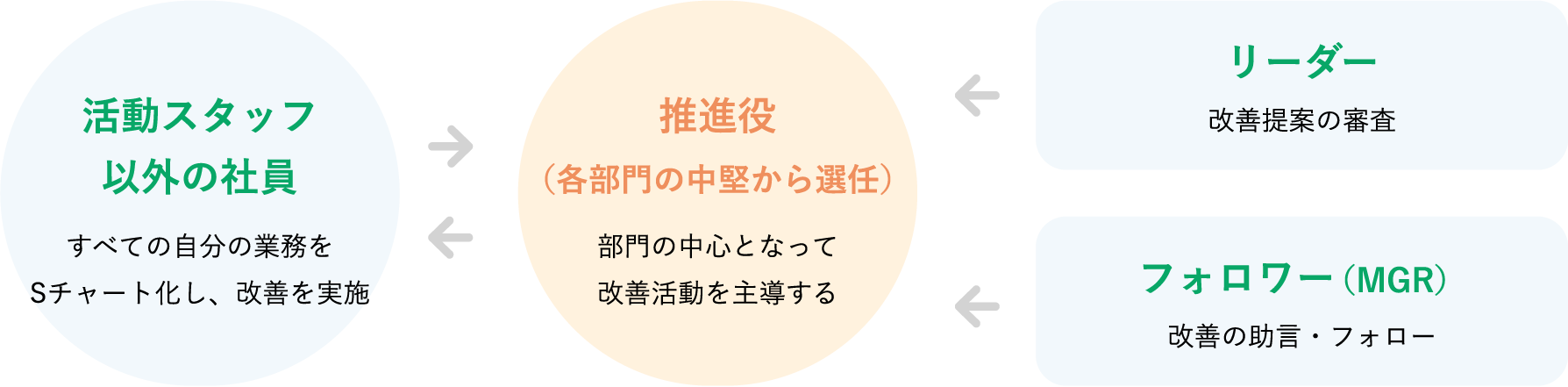

推進体制

推進役や社員が活動を通して業務を改善し、学習と成長をマネージャーが応援していく体制

実際の活動について

まず行ったことは徹底的な業務の見える化です。各自が業務のリストアップを行うのですが、

1人100件を目標に1ヶ月以内に自業務の全部の洗い出しを行いました。

通常、業務担当や職掌はあっても自分が実際にどのような業務をしているかを明確に把握していないことが多く、

そのため漏れが発生して改善の俎上に載らない業務が生まれてしまいます。

そのことを防ぐために、思いつく限りすべての業務をリストアップして見える化をしました。

これらの活動は通常の業務をこなしながら行います。

かなり時間的負担が大きく、平均すると約10%もの業務時間増となります。

特に連続する祝祭日の前や月末月初などの忙しい時期にはかなり大変な思いをした社員も多く出ました。

それでもなんとか全員ががんばった結果、社員40名で約3800件の見える化をすることができました。

その中には、お客様へのお茶出し、メルマガの閲覧、立替払いの精算、稟議書の捺印、商品開発など

軽重を問わずあらゆる業務が洗い出されました。

次に見える化された業務について開始から6ヶ月以内に全てSチャート化いたしました。

専用ソフトで簡単に作れるとは言え、業務を正確に記述するのは相当の時間がかかりました。

さらに、作成したSチャートについては月5件以上の改善提案の作成提出も義務といたしました。

それがこちらの図になります。その結果改善提案数は3198件にもなりました。

また個人の改善だけではなく、部門レベルの部内検討会を週一ペースで行いました。

個人の改善提案の発表や討議、横展開、部門レベルの改善等を検討する会議で、現在でも多くの部門で続いています。

さらにアウトプット検討会という全社レベルの検討会も開かれています。

これは月一ペースで開催され、各部の優秀提案や改善状況が発表され、改善提案に対しては

社長から社員まで等しく質問や意見の発表をします。また検討中で実施されていない改善提案に対して

社長が即決することもしばしばありますので、改善のスピードが早くなりました。

活動の成果

まず会社全体の業務削減時間は2017年から6月から2018年9月までの間に17317時間

一人当たり444時間の業務が削減されました。これは有効労働時間の約40%に当たります。

ここで言う「有効労働時間」というのは実際に作業を行っている時間数のことです。

例えば年間2000時間の労働時間があった場合でも、その中には待機時間や移動時間、トイレや喫煙、ぼーっとしてる時間、

立ち話など直接的な作業とは関係ない時間がかなり含まれており、それらを除くと1000時間から1200時間になると言われています。つまり2000時間の労働時間があったとしても実働は50から60%になります。

この考えから削減時間を換算すると約40%の業務時間の削減が達成されたということになります

個別の改善は本当にたくさんありますが、例をあげるとまず「月次決算半減」があります。

いままでは10稼働日で出ていたものを5日で出せるようになりました。

それまでの業務フロープロセスのすべてを見直し、以下のようなアクションを行いました。

ただし、このときは基幹システムの改善は行わず、プロセスの改善のみでした。

改善アクション

請求書の送付を

請求書の送付を

早めてもらうよう依頼 難しい場合には

難しい場合には

FAX・メールを依頼 ネットから請求書を

ネットから請求書を

ダウンロード(マクロを活用) 利用明細から集計

利用明細から集計 4次業務の

4次業務の

改善・廃止 リードタイムの短縮

リードタイムの短縮

その結果、2018年6月を目標に決算期間の半減を目指しましたが、4月に前倒しして達成できました。

また就業時間は30分短縮されて1日の労働時間が7.5時間になりました。残業も0となり隠れ残業も大幅に減少しました。

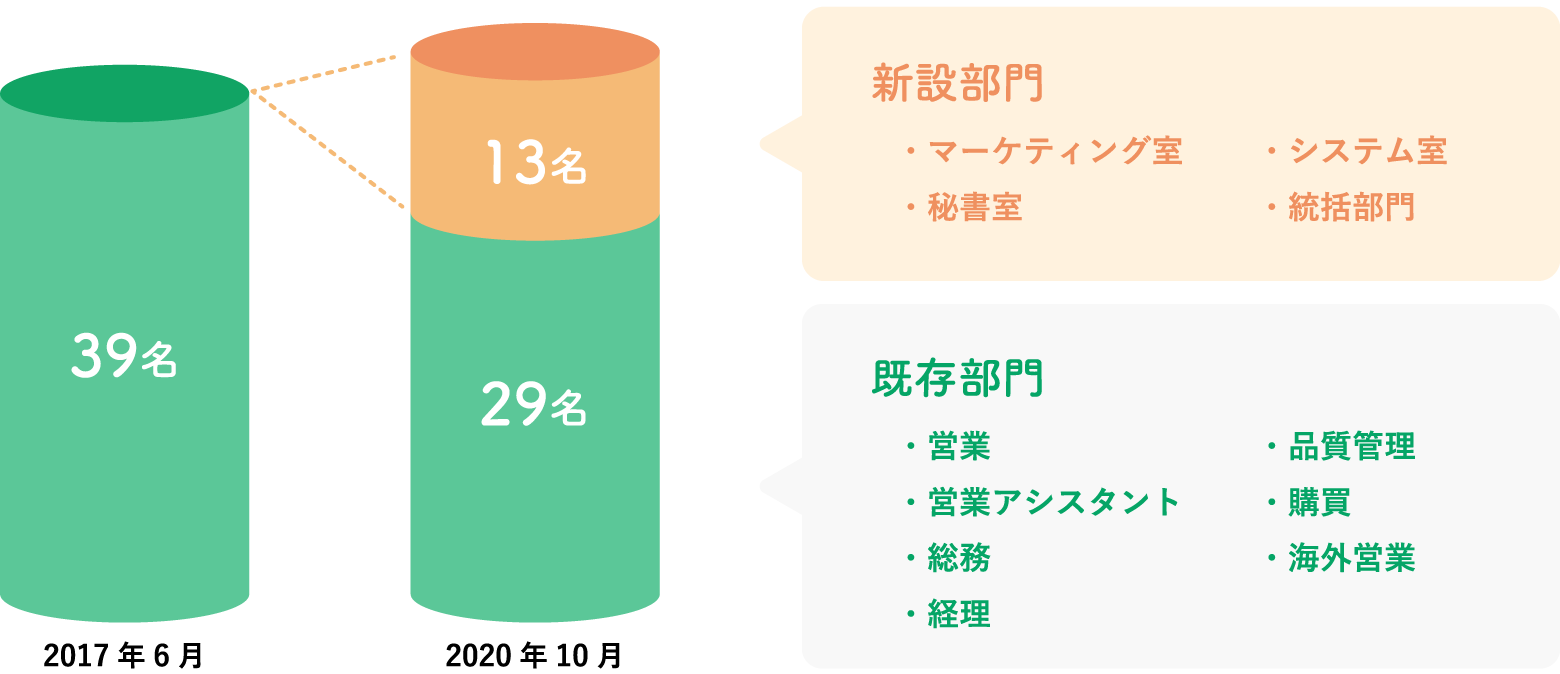

さらに部門の人員構成が変化し、社員の3割以上がマーケティング、システム、秘書などの新設部門に移動しました。

それだけではなく、社員がステークホルダーに喜んでいただくために割く時間を増やすことが出来ました。

30%の社員が新設部門に異動

活動の今後について

FISH活動は2020年初頭のコロナウィルスの流行に伴う在宅勤務体制への急遽移行のために一時期中断しましたが、

その後再開されました。改善提案の作成も在宅で、アウトプット検討会はリモート会議で行われています。

今後オカフーズがさらにステークホルダーの皆さまにお役に立つための時間を捻出するために、

その供給源である改善活動は続けていきます。

- TOP>

- Company Information>

- Management Philosophy | Oka Foods